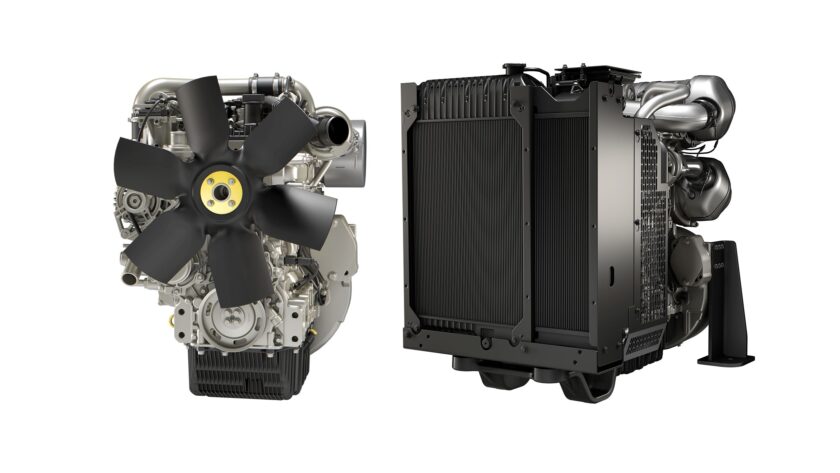

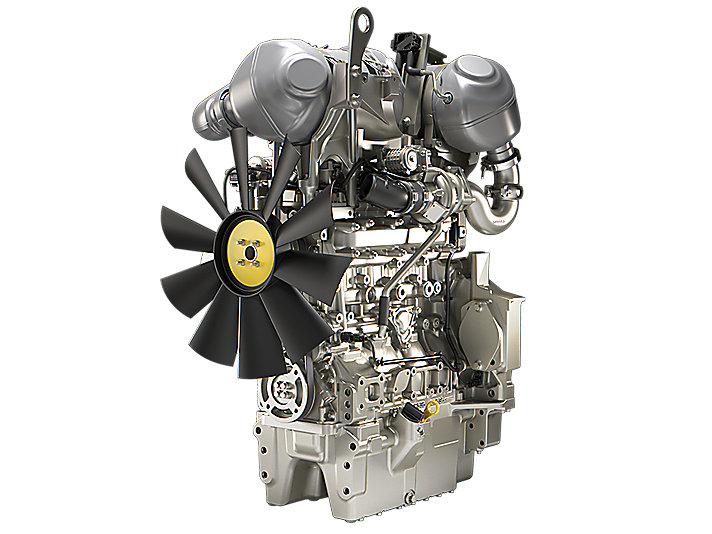

Designed and developed with OEM integration and end-user utilization in mind, the four-cylinder Perkins “904J” series engines have seen their installations exceed one hundred thousand units since the production of the first engine in 2019. This volume of applications has materialized across a wide range of fields, from self-propelled machinery used in agriculture and earthmoving sectors to stationary applications in the realm of water pumps and power generation systems. This success has been achieved through a design approach that prioritizes space reduction and ease of integration into machinery, culminating in a series calibrated based on two different displacements: two liters and 800 cubic centimeters, and three liters and 600 cubic centimeters, without compromising performance objectives and maximizing power density.

Initially, three versions were launched on the market, considering Stage V-certified units in terms of emissions. In the two-liter and 800 cubic centimeters displacement, the series comprises the “904J-E28T” and “904J-E28Ta” units, featuring four-cylinder direct injection inline architecture with a unit displacement of 699 cubic centimeters derived from 90-millimeter bore and 110-millimeter stroke, capable of delivering 55 kilowatts of maximum power, 75 horsepower, at respective speeds of two thousand 200 and one thousand 900 revolutions per minute, maintaining it constant until the maximum speed of two thousand 400 revolutions.

This performance defines a specific power of almost 27 horsepower per liter with average piston speeds just below nine meters per second. Different torque values depend on the supercharging system. Ranging from 300 newton-meters at one thousand 600 revolutions to reaching 380 newton-meters already at one thousand 360 in the version with aftercooler “Ta”. Different performance is also reflected in the values of effective mean pressure, 13 and a half bars for the “T” version and just over 17 in the “Ta” version. Available only in this latter version is the “904J-E36Ta” unit with a unit displacement of 905 cubic centimeters derived from 98-millimeter bore and 120-millimeter stroke cylinders. 100 kilowatts are available at two thousand revolutions, 136 horsepower, up to the nominal speed of two thousand 200 revolutions, while the torque reaches 550 newton-meters at one thousand 500 revolutions per minute. These performances are also confirmed in the fourth version where the unit with a three-liter and 600 cubic centimeters displacement was proposed, the version with a structural base dedicated to applications on agricultural tractors.

Units capable of leveraging nearly 38 horsepower per liter of specific power combined with dimensions capable of keeping total dimensions below 300 cubic decimeters, achieving a power-to-volume ratio of almost 460 horsepower per cubic meter and a power-to-weight ratio of less than 3 kilograms per horsepower. Produced at the English plant in Peterborough, England, over the years, the units have been enriched with an additional version.

Reengineering Packages Also Available

At the end of 2022, both the “E28T” and “E36TA” engines were proposed in the “Industrial Open Power Units” version, designated as “Iopu,” in Stage V and Tier 4 Final certification with the aim of further facilitating installation on machinery and reducing implementation costs for reengineering. These units are provided with control units and post-treatment system sensors already installed, optimized with a view to reducing space requirements, together with the fuel filter including a probe for water presence in diesel and, optionally, a control panel for monitoring unit operation.

Perkins “904J” Series, Also Compliant with Chinese Standards

The range was further expanded in January 2023 to meet the Chinese market with the start of production of units certified according to the China Nonroad Stage IV regulations at the Wuxi plant in China. Among the advantages offered by Perkins units are also ease of maintenance thanks to the positioning of service systems on a single engine side, the presence of a hydraulic belt tension adjustment system of the long-life type, and a post-treatment system with automatic regeneration of the DPF filter.

Built to Last

Perkins has recently introduced a new line of cylinder liners to refurbish “1100” series engines when worn from continuous use. These components are designed to allow the restoration of individual cylinders, allowing, where possible, the retention of original factory pistons without compromising engine balance. The new components align with Perkins’ philosophy of prolonging the life of its engines by limiting machine downtime for workshop repair. Composed of the same material as the engine blocks, the new “1100” series cylinder liners have been validated by Perkins to ensure optimal stability and durability. The components will be available through Perkins’ global distributor network.

Title: Perkins “904J” Series Engine: Surpassing the Hundred Thousand Mark

Translation with ChatGPT